OptoTech Optikmaschinen GmbH

Sandusweg 2-4, 35435 Wettenberg, Deutschland

[email protected]

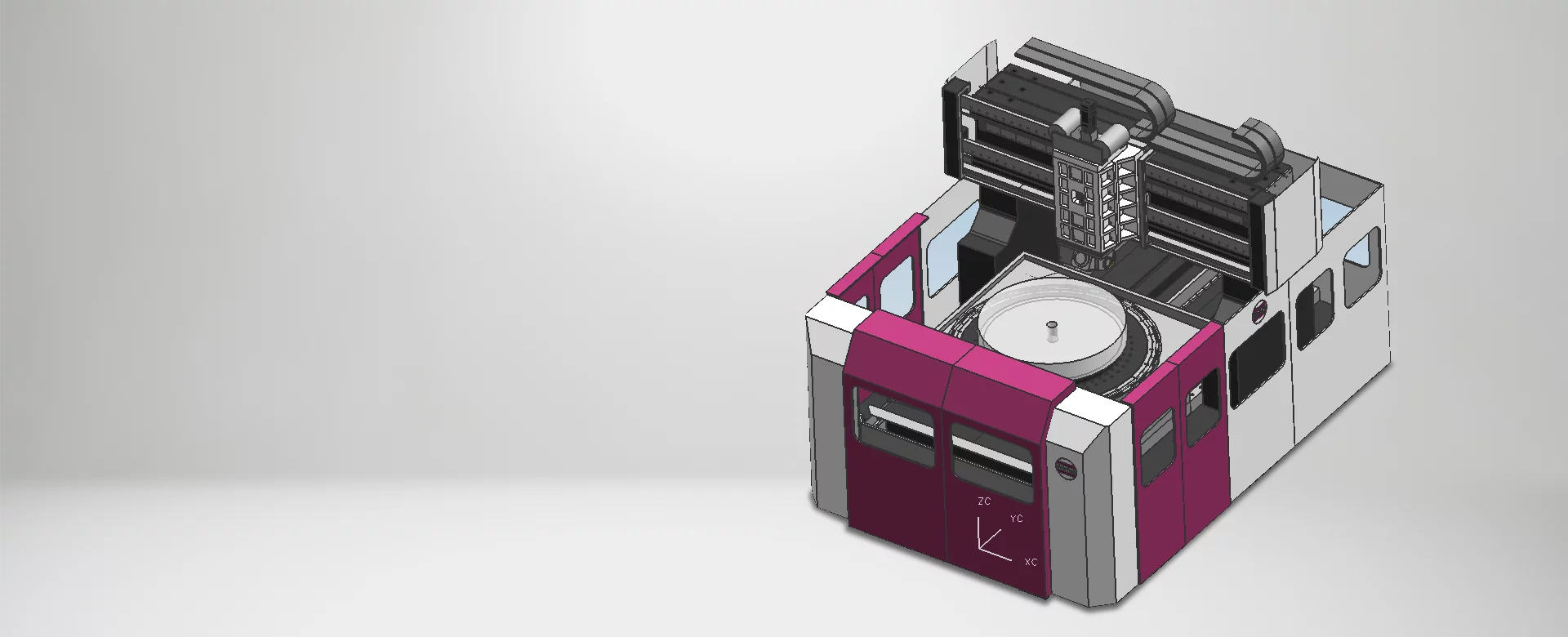

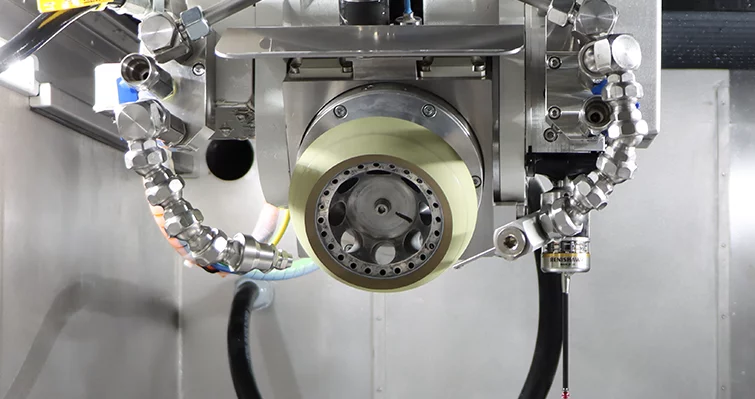

The Ultra-Precision Grinding Machine UPG 1500 CNC was especially designed for processing of high-end ASTRO optics up to diameter 1500 mm. Whether spheres, aspheres, or freeform surfaces, the UPG 1500 CNC offers highest precision grinding (all axes mounted hydrostatically). This compact and high efficient design allows an optimal production of all important future parts in the area of ASTRO-Optics, EUV-Optics and aerospace technology.

Contact request

Sandusweg 2-4, 35435 Wettenberg, Deutschland