OptoTech Optikmaschinen GmbH

Sandusweg 2-4, 35435 Wettenberg, Deutschland

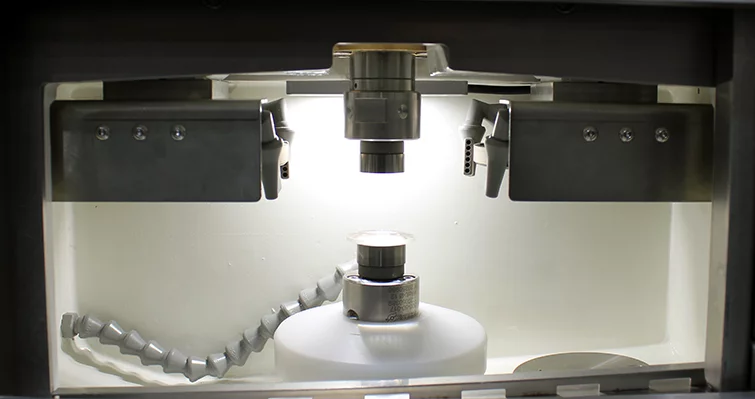

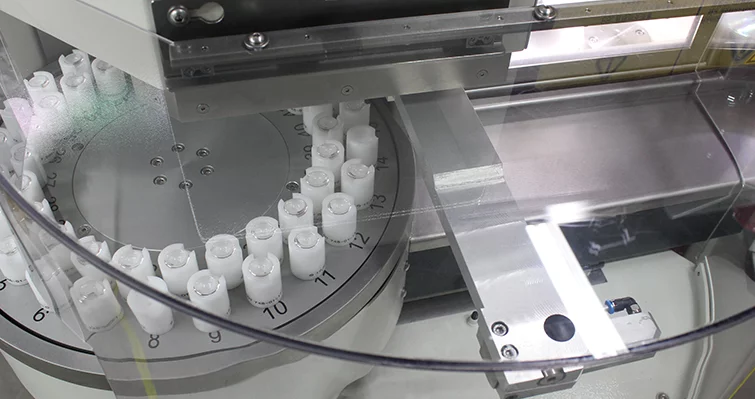

The ZM 50 CNC-TC is a simultaneously working edge processing machine in highest precision. The high quality software module allows even the production of complex edge geometries.

Contact request

New clamping technology:

Clamping spindle (W-Axis) equipped with a new, electronic (servo) clamping force- and positioning control, which allows repeatable adjustment and regulation of very low clamping forces. The combination of new, innovative clamping spindle guides leads to maximum dampening and rigidity. Due to this, higher stock removal rates can be achieved and unwanted marks of the centering bells can be eliminated

The completely new designed software package „OptoEdge“ allows programming of complex edge geometries:

Sandusweg 2-4, 35435 Wettenberg, Deutschland