OptoTech Optikmaschinen GmbH

Sandusweg 2-4, 35435 Wettenberg, Deutschland

Generally the cycle times of generators are 2-3 times faster then the cycle times of the polishing machines. Due to this, you need 2-3 polishing machines and one generator to synchronize a processing line. Alltogether you need 4 machines.

The perfect relationship would be 1:1, one polisher and one generator. But that requires the cycle times of the generators and the polishers to be approximately the same.

In 2001 OptoTech developed the 3C Technology, which enhanced the surface qualities of the generators in a way that the polishing times decreased to the generators cycle times. The term „3Cut“ (3C) describes a procedure in which a surface is processed in 3 steps:

Pre- and fine grinding with OptoTech KombiTool+. The second tool spindle is equipped with a diamond pellet tool, a forming tool as used in the polishing process. The kinematics are thereby similar to the polishing process. Moreover the pellet tool is performing an additional oscillation movement around the radii-centre of the processed surface.

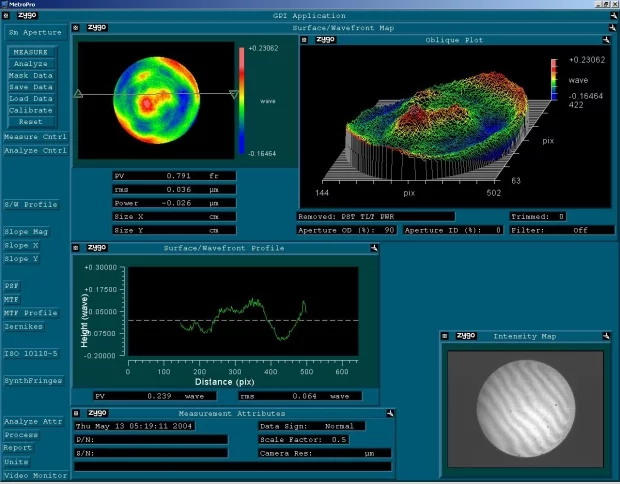

As a result you will get an almost pre-polished surface that can even be measured by an interferometer.

Due to the considerably better surface quality, the polishing times can be shortened by approx. 30-40%. So an ideal 1:1 relationship of the generator and the polisher can be realized. With this synchronized production line you can cut your investment costs drastically because you only need 2 machines instead of 4 to synchronize a production line.

The 3C Technology wasn't only developed for the production of high volumes. You can also use it for small series with a high repeat rate.

Interferogram of a 3C-processed lens

Even on optics with big diameters, where the polishing cycle is comparatively long, 3C can realize savings for your polishing time.

Your Benefits at a Glance:

Sandusweg 2-4, 35435 Wettenberg, Deutschland