OptoTech Optikmaschinen GmbH

Sandusweg 2-4, 35435 Wettenberg, Deutschland

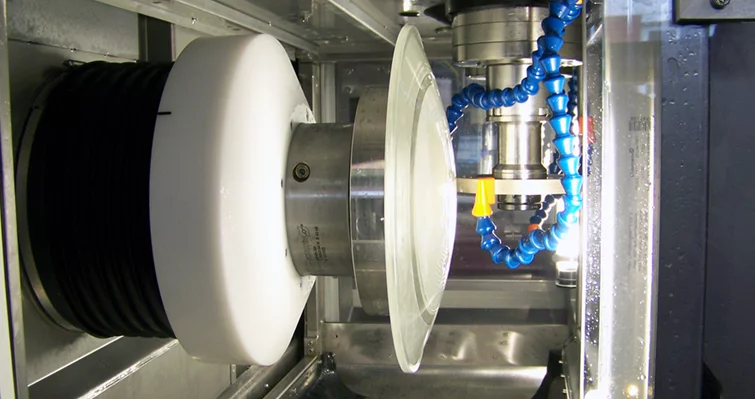

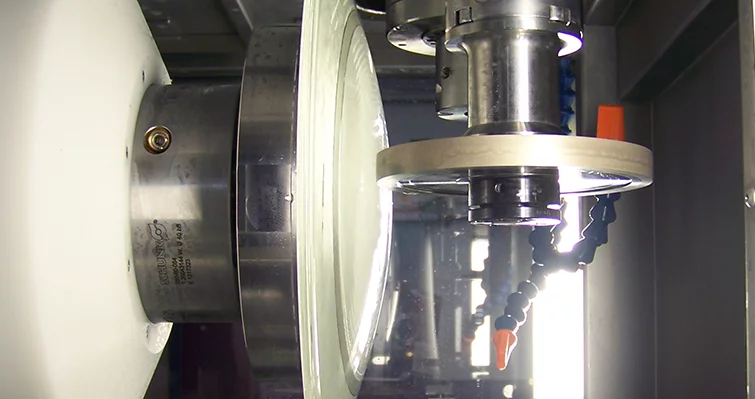

The 4-axis ASM 300 CNC-Plus is the world wide most precise pre- and fine grinding machine for aspheres and freeform surfaces. Hydrostatic bearings for all linear axes and a workpiece spindle combined with a high class asphere software quarantee surfaces in highest precision. The ASM 300 CNC-Plus offers high quality grinding due to 2 interpolating axes.

Contact request

Sandusweg 2-4, 35435 Wettenberg, Deutschland