OptoTech Optikmaschinen GmbH

Sandusweg 2-4, 35435 Wettenberg, Deutschland

[email protected]

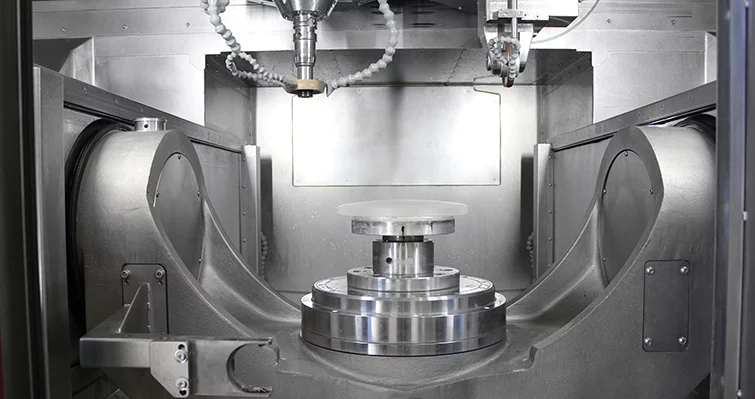

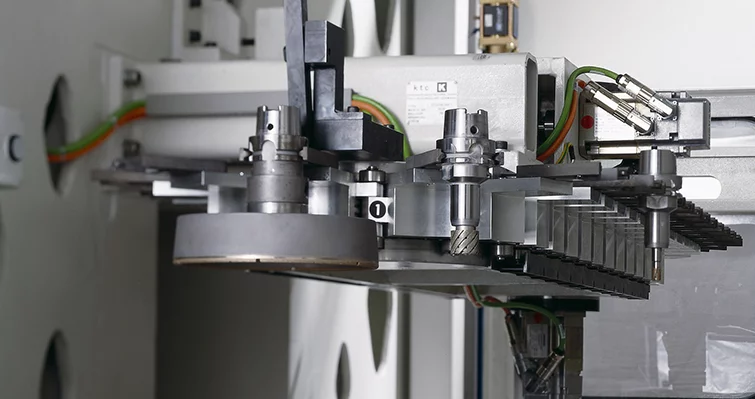

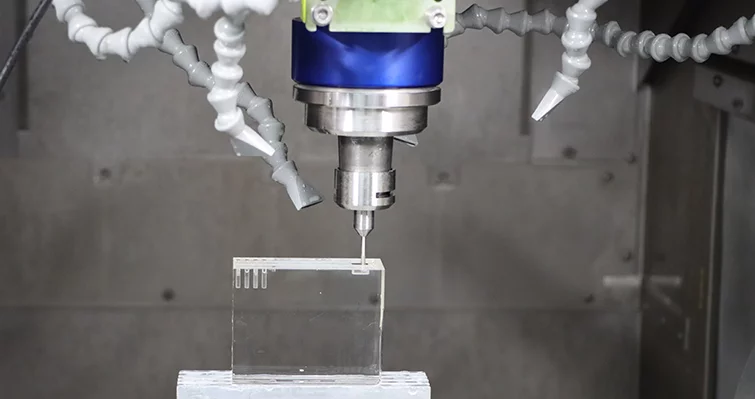

The OptoTech optical processing center MCG 500 CNC Compact provides you with grinding technology for all optical materials with highest precision and flexibility. Whatever you want to produce, whether aspheres, spheres, edging, prisms, cylinders. 3D-optics or drilling holes, the MCG 500 CNC Compact is the perfect machine for these tasks. Up to 5 CNC axes and an innovative tool concept deliver the requested flexibility.

Contact request

Standard Cycles:

Machine Options:

Software Options:

Sandusweg 2-4, 35435 Wettenberg, Deutschland